Services

LUBRICATION MANAGEMENT PROGRAM

A hydrocarbon management review and improvement process which has a strong focus on contamination control has demonstrated significant savings in equipment reliability and maintenance costs.Next to the correct selection of a lubricant, maintaining a clean and moisture free system is paramount to prolonging both machine and oil life. Numerous research institute studies and industry case studies have demonstrated the positive gains that can be attributed to improved fluid cleanliness levels. Increased component life and prolonged oil life are the two most obvious cost benefits, however there are numerous secondary benefits including reduced inventory, reduced unscheduled outages, etc.

Clean Lube Solutions introduces a program to assist organisations with their journey towards best practice in Lubrication Management. The features & benefits of the Clean Lube Solutions program includes the following:

- Provides a structured approach incorporating the vital steps to introduce and carry out a world class lubrication management program

- Captures all areas of lubrication managment and promotes sustainability of the program

- Carried out by a third party organisation however focused upon coashing ad empowering site personnel

- Provides a valuable resource to organisations enabling best practices to be sourced and instigated

- Following a structured approach allows for maximum benefit from both time and money spent

- Incorporates a measurable system of attaining improvements in lubrication management

Clean Lube Solution’s Lubrication Management Program has been designed according to the requirements of many organisations who strive for excellence in hydrocarbon management. This includes those companies wanting to commence the process and also those who have already instigated improvements. The program is based around a structured and measurable system that can assist organisations who are at any stage of a Lubrication Management Program. It is paramount that the instigated program and improvements made are sustainable, irrespective of personnel changes. Clean Lube Solutions are focused on coaching site personnel during this process and have designed the program to be integral with the site systems.

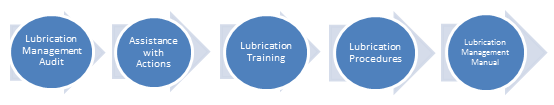

The steps involved in Clean Lube Solution’s lubrication management program include:

LUBRICATION MANAGEMENT AUDIT

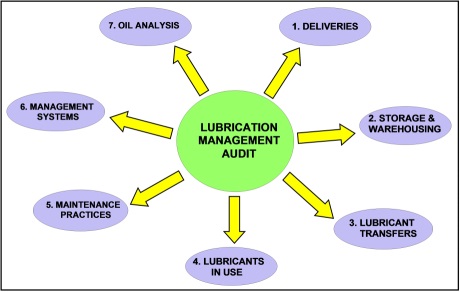

The Purpose of the Lubrication Management audit is to identify the gaps between current site hydrocarbon practices and best practices in industry and to make recommendations on how to eliminate those gaps.

The audit process is a structured approach that follows the life cycle of lubricants and diesel as detailed in Figure below. This commences prior to products delivered to site with specifications, cleanliness, etc through to recycling or waste streams.

All areas related to hydrocarbon management must be reviewed as they impact upon the effectiveness and sustainability of the review and improvement process. It is important to implement training, procedures, processes and practices that will allow the program to be self sustaining, irrespective of individuals or management.

A question set and rating system is utilised to assess the current state of hydrocarbon management across the site. Both observations and responses to the questions will identify deficiencies that can be acted upon. Each question is rated against best practice in the industry and provides an assessment of individual oil systems as well as procedures, processes and practices. Use of the question set has many advantages including the following:

Ensures a complete and consistent assessment of hydrocarbon management is carried out.

- Assesses each area against industry best practice and identifies gaps.

- Identifies a comprehensive action list, and

- Allows for consecutive assessments to monitor improvements.

A detailed audit report with photographs and a list of actions is presented.

OIL ANALYSIS

Clean Lube Solutions has developed a number of Oil Analysis Programs. For example our Turbine Oil Analysis Program is essentially a structured and proactive approach to monitoring in-service turbine oil. The purpose of such a program is to aid the overall extension and trouble free operation of the turbine fluid, detect the likelihood of insoluble formation within the oil and to offer proactive measures to bring the oil back within specification when required.

Features & Benefits :

Equipment

- Optimisation & Extension of Oil Life

- Early Detection of Sludge, Varnish & Laquer

- Reduction in complexity and cost of Oil Drain & Flush

Operational

- Effective Oil Analysis Program carried out and overseen by a specialist organisation

- A comprehensive bundle of oil tests carried out to optimise the program

- Oil analysis testing frequencies that will allow for rapid detection of system oil changes

- Effective reporting and feedback on the analysis results

- Periodic site visits to review the analysis results and program, discuss issues and perform training as required

- Consultation on oil related issues

- Source of oil treatment equipment (Vacuum Purifiers, Filtration Equipment) – Hire or Sale

- Assistance with oil changes (Procedures, Equipment and Personnel)

Phone: +61 7 3800 9444 for further information on our Oil Analysis Programs

CONSULTING

Consulting can include advise and project management on the following:

-

Tank cleaning, breathers, safety vent valves, filtration & general equipment

-

Cleanliness control

-

Filtration, flushing, water removal & elimination, documentation of standards & specifications

-

Oil analysis

-

Laboratory selection, site program review, testing and target selections

-

On-site oil testing

-

Setting up of on-site labs & lube rooms, equipment/test selection, specifications, procedures & training

-

Lubrication management processes

-

Handling, distribution & lubricant consolidation