Oil Transfer Containers

The first best practice solution that fully isolates oil from the environment during transfer.

Applications

- Transferring small volumes of oil

- Topping off reservoirs

- Small volume storage

Key Benefits

- Isolates and protects oil to meet bestpractice standards with breathers and ISO B quick connects

- Provides variable flow control with triggermechanism

- Square containers store 27% more volumeper square foot than round containers

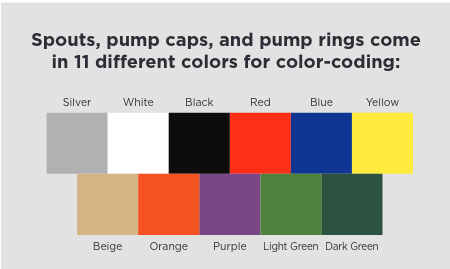

- Prevents cross contamination and provideseasy lubricant identification with 11-color-coding options and tagging system

- Minimizes inventory management withmodular, interchangeable spouts, collar rings,and pump caps as the only color-codedc omponents

Available Options:

Dispensing Lid

- Standard vent plug or desiccant and non-desiccant breathers

- Optional 1/2″ ISO B plug for filling

Spout options

- 5″ or 8″ rigid or 16″ extended spout

- 5″ rigid has a 1″ tip opening

- 8″ tip opening options are 1″, 1/2″, or 1/4″

- Eleven color options

Pump Lid

- Standard vent plug or desiccant and non-desiccant breathers

- Optional 1/2″ ISO B plug for filling

- Cap for storage or pump for transferring oil

- Eleven cap and pump ring color-coding options

Container

- 1 Gallon/4 Liter, 1.8 Gallon/7 Liter,2.6 Gallon/10 Liter sizes

Performance

For keeping oil clean and dry during storage and transfer to machinery with a maximum operating viscosity range of ISO VG 680 (3000ssu/648cSt) at 100°F/38°C within ambient temperature ranges of -40°F to 176°F (-40°C to 80°C)

Wetted Materials & Components:Dispensing Lid and Spout

- Nylon

- 304 Stainless Steel

- Steel

- Buna-N

- HDPE

- PTFE

Pump Lid, with Pump

- 304 Stainless Steel

- Steel

- Fluoro-silicone

- Silicone

- Nylon

- PVC

- Polyurethane

- Aluminum

- Vinyl

- HDPE

Container

- HDPE

Chemical Compatibility

- Recommended for mineral-based industrialoils and most synthetic oils. HDPE containers will not chemically react with oil or additive packages.

Specifications

By the Numbers:

1 – Three Practical Container Sizes – Space saving square containers in three sizes – 1 gallon/4 liter, 1.8 gallon/7 liter, 2.6 gallon/10 liter

2 – Dispensing and Pump Lids – Hex and ridge design for strength and an ergonomically designed handle for a firm grip on the dispensing lid

3 – Trigger Mechanism – Precise pour control and locking mechanism for ease of use, and a special-ly designed spring and o-rings keep lubricants sealed until the trigger is engaged

4 – Port for Optional Breather – Optional non-des-iccant (DC-ND-2) or desiccant (DC-BB) breathers can be added to control moisture and contami-nants, basic lid comes standard with a vent plug

5 – ISO B Port – Optional 1/2″ ISO B quick connect ports for best practices oil transfer to container

6 – Interchangeable Spouts – Interchangeable spouts come in 5″ or 8″ rigid and 16″ extended, three tip sizes, and 11 colors

7 – Spout Cap – Spout cap prevents contamination of oil during storage and can be clipped onto the side of the spout during use

8 – Pump Color-Coding Cap and Ring – Color-coding cap for lid and ring for pump come in 11 colors and offer a best practices color-coding solution

9 – Pump – Heavy duty pump with D-ring down-stroke handle delivers 1 liter with approximately 12 strokes

10 – Pump Hose – Pump hoses available in 5′ or 10′ lengths, and with a dispensing nozzle or 1/2″ ISO B coupler

11 – Lubricant Tagging System – 2″ X 3″ color-cod-ing labels with recommended color & pattern tagging system